- A-29, Industrial Area, Site IV,

Sahibabad, Ghaziabad, UP, India. - (+91-120) 2896063

info@bhartiyagroups.com

Oxygen Liquid Plant, We are also manufacturing and supplying cryogenic liquid oxygen/nitrogen plants as a product mix mode. With leakproof stainless steel column and skid mounted version for high purity medical and industrial oxygen. You can get from 30% upto 100% Liquid oxygen/nitrogen out put. The output of liquid oxygen/nitrogen is stored in a liquid oxygen tank.

1. Compression Of Atmospheric Air By Air Compressor

The free saturated air is sucked from atmosphere through a highly efficient dry-type suction filter into the first stage of the horizontal balanced opposed, lubricated reciprocating air compressor. Compresssed air is chilled to 12 degree centigrade in a chilling unit ata temperature of 12 degree centigrade to a moisture separator where the condensed moisture gets removed before entering into Molecular Sieve Battery. Before sending the air to MOLECULAR SIEVE BATTERY, air is passed through an OIL ABSORBER where air becomes oil free.

2. Purification of Air By Process Skid

Chilled air passes through the Molecular Sieve Battery consisting of Twin Tower packed with Molecular Sieves to remove moisture and Carbon dioxide present in the air. Molecular Sieve Battery operates on Twin Tower System, when one tower is under production the other tower is regenerated by passing waste Nitrogen gas at 200 degC through a reactivation heater. After interval of 8 to 10 hours, the tower under production gets exhausted and regenerated by similar process before use and thus the cycle continues. Any dust particles gets filtered in the DUST FILTER before air enters the AIR SEPARATION COLUMN.

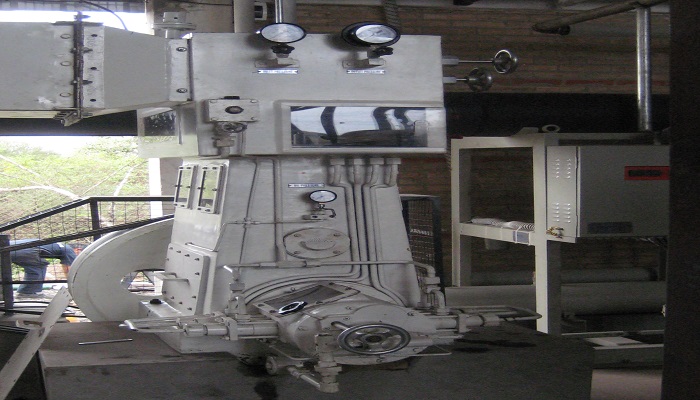

3. Cooling of Air By Expansion Engine (Expander)

The process air before liquefication in the air separation unit needs to be cooled to temperatures sub-zero (cryogenic). The main portion of the air after the process skid enters the expansion engine through the heat exchanger no. I after pre-cooling. The temperature of the air drops to around -165degC by the Expander which is a very highly efficient advanced design with Teflon piston rings and completely hydraulic mechanism with leakproof ball valves.

4. Separation If Liquid Air into Oxygen And Nitrogen By Air Separation Column

Chilled, Oil free and moisture free air enters into multi-pass HEAT EXCHANGER NO.I where it gets cooled to (-80) degC by cold gained from outgoing waste Nitrogen and Oxygen. A part of air this enters a multi-pass HEAT EXCHANGER NO. II or LIQUIFIER made of special Alloy tubes. This air cools to (-170) degC before passing through an expansion valve. Due to joule Thompson Effect, after the expansion valve. Due to joule Thompson Effect, after the expansion valve, air gets further cooled down and gets liquified before entering into bottom column is known as rich liquid.

The rich liquid in the bottom column enters into feed tray of top column enters into feed tray of top column. Similarly the liquid nitrogen called POOR LIQUID enters into top column as a reflux & it takes away the latest heat of condensing Oxygen and gets vapourised whereas the liquid Oxygen flows down the trays of the top column into the Condenser passes through a Sub-Cooler to a LO Pump.

5. Compression and withdrawal of liquid and gaseous oxygen for storing in storage tank and cylinder filling

Model |

BO-50L |

BO-100L |

BO-200L |

BO-300L |

BO-500L |

|

Capacity |

Oxygen |

50Ltrs/hr |

100Ltrs/hr |

200Ltrs/hr |

300Ltrs/hr |

500Ltrs/hr |

Nitrogen |

200m3/hr |

300m3/hr |

800m3/hr |

1200m3/hr |

2000m3.hr |

|

Purity |

Oxygen |

99.60% |

99.60% |

99.60% |

99.60% |

99.60% |

Nitrogen |

96%-99.9% |

96%-99.9% |

96%-99.9% |

96%-99.9% |

96%-99.9% |

|

Power Connected |

125KW |

250KW |

400KW |

500KW |

950KW |

|

Power consumed |

90KW |

150KW |

280KW |

400KW |

700KW |

|

Power Supply |

415 Volts |

415 Volts |

415 Volts |

415 Volts |

415 Volts |

|

Working Pressure |

100kg/cm2 |

95kg/cm2 |

90kg/cm2 |

90kg/cm2 |

90kg/cm2 |

|

Air Capacity |

300m3/hr |

600m3/hr |

1200m3/hr |

1800m3/hr |

3000m3/hr |

|

Areas required |

8Mx12M |

14Mx15M |

14Mx15M |

14Mx15M |

14Mx15M |

|

Assembly Height |

7.5Meters |

9.5Meters |

9.5Meters |

9.5Meters |

10Meters |

|

Weight |

19Tons |

30Tons |

50Tons |

60Tons |

80Tons |

|

Note:

Oxygen liquid plant, the output of liquid oxygen can be stored in a liquid oxygen tank. Liquid Nitrogen can be available as a by product simultaneously upto 99.999% (PPM GRADE) purity. The plant is extremely versatile and all the possible product variants are possible you can either take 100% Liquid oxygen out put or 50% Liquid oxygen output directly into cylinders or 50% Liquid oxygen and 50% Liquid nitrogen

High efficiency filter supplied with the compressor

This is a multistage heavy duty water cooled air compressor with fly wheel inter cooler, foundation bolts, motor pulley, v belt, guard and slide rails and air filter. This is used to compress atmospheric air complete with motor and Starter.

Complete with motor and starter with hydraulic valve control, bursting disc for safety, complete with flywheel pressure gauge, motor pulley v belt, belt guard, slide rails inter connected copper pipes (inlet and outlet) hydraulically operated high efficient engine with ball type of valves stainless steel liner vertical type of German Design.

Air Separation Column (cold box complete) with outer steel casing, main heat exchanger, liquefier, bottom column, top column, condenser, sub cooler, liquid oxygen /nitrogen filter. Cooling pipes, insulation Material, digital electronic temperature meter pt100 sensor, DP gauge manometer, expansion valves, interconnecting piping, purity scanner for oxygen. (The internal piping of the lower and upper column and the trays in cold box are made of SS304L or SS316L and not Aluminium or copper).

PLC based water-cooled Air Chiller with imported open screw compressor from Bitzer (Germany) complete with SS 304 evaporator with SS shell and SS tubes, SS baffle plate, SS tie rod and SS tube sheet

For filling high-pressure oxygen to cylinders. It consists of main high-pressure isolation Valve and Pigtail connection with individual industrial regulation valve with pressure gauge and Safety Relief Valve.

Induced Draft-Rotary Sprinkler type with Aluminium Casting Fan, FRP Body with suitable Electric Motor for maintaining the circulating water temperature between the Hot well and Cold well for optimum performance of the plant.

For circulation of water to Hot and Cold Well Centrifugal pump Mono Block type, RPM 1440

For supply of electricity to individual motors. It has a bank of on/off switches and fuses. This enables the Operator to control all the Motors from one point.

We Wish This article will Help to Under stand Oxygen Liquid Plant.

People Also Like : Liquid oxygen plant | Manufacturer of oxygen plant | Manufacturer of oxygen plants | Oxygen factory | Oxygen cylinder filling plants | Oxygen plant exporter | PSA Oxygen Plant | Air separation plant | Air separation plants | Oxygen production plant | Oxygen production plants | Oxygen plants India | Oxygen plant India | Oxygen plants supplier | Oxygen plant supplier | Oxygen plants | Oxygen plant | Oxygen plants manufacturer | Oxygen plant manufacturer | Oxygen Factory | Oxygen Plant India | PSA Oxygen Plant