- A-29, Industrial Area, Site IV,

Sahibabad, Ghaziabad, UP, India. - (+91-120) 2896063

info@bhartiyagroups.com

The government has scaled up oxygen production plants to 18,836 metric tonnes (MT) towards preparedness for the impending Covid-19 wave

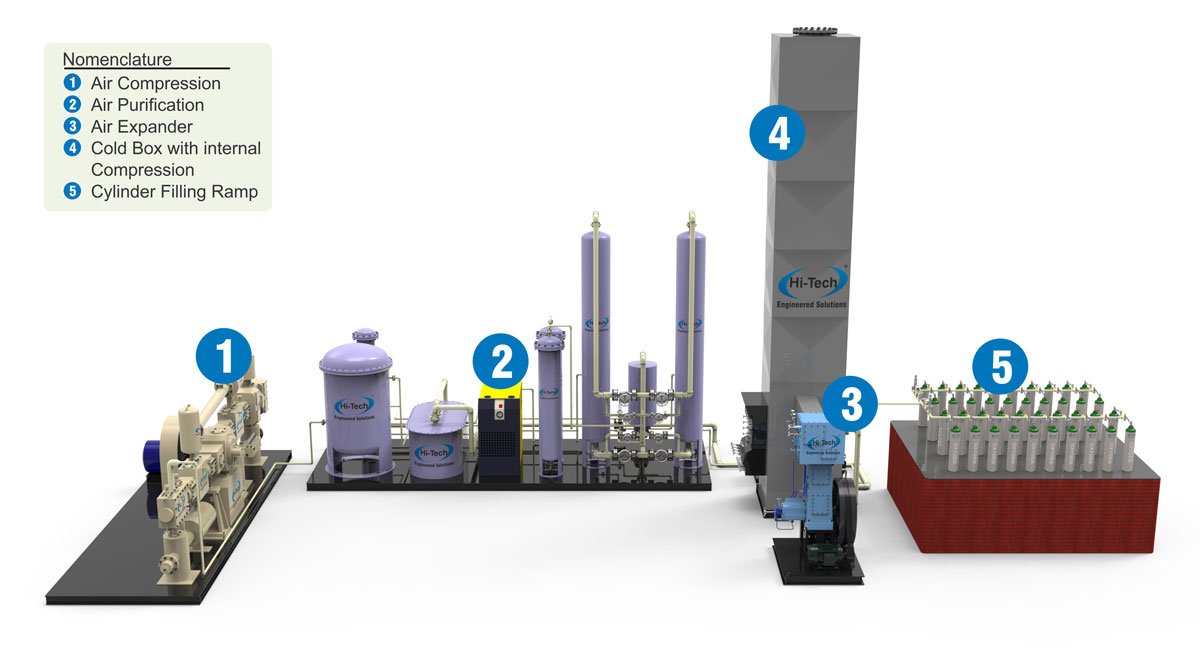

The cryogenic oxygen plant is designed to take free air from the atmosphere containing moisture and bring down its temperature to a value below freezing point so as to liquefy it

The government of Ukraine, in particular the Ministry of Finance, signed a contract for the purchase of 225 oxygen plants for COVID-19 patients

The 500-litre per minute oxygen production plant at Government Medical College, Jammu

Pressure swing adsorption (PSA) oxygen generating plants are a source of medical-grade oxygen

The cryogenics oxygen plant produces on-site, high-purity oxygen for industrial production processes and for medical purposes

The cryogenic oxygen plant is an industrial facility that electrolytically produces liquid oxygen in large quantities

Cryogenics oxygen plant is used to freeze air or gas into liquid or solid state

Air Separation Plants (ASPs) are gas separation facilities that use air, instead of liquid carbon dioxide, to separate the other gasses in natural gas streams.

Air separation plants allow you to use air as the carrier gas in cryogenic applications, displace the burden of liquid oxygen imports and costly liquid nitrogen refueling.

Liquefied oxygen can be produced by combining liquid nitrogen and air at temperatures up to -162 degrees Celsius

Nitrogen gas is required for many key industrial procedures

LINEX engines are designed for high-horsepower applications

Steel production uses cryogenic equipment to transport gases like hydrogen

Transport and storage are straightforward

There is high demand for oxygen in the country

RIL are increasing production of liquid medical oxygen.

We are the leading company around the world.