- A-29, Industrial Area, Site IV,

Sahibabad, Ghaziabad, UP, India. - (+91-120) 2896063

info@bhartiyagroups.com

The cryogenic oxygen plant is designed to take free air from the atmosphere containing moisture and bring down its temperature to a value below freezing point so as to liquefy it

Dr Angelique Coetzee -- the South African general practitioner who first very perceptively noticed the arrival of Omicron in patients in her surgery in Pretoria

WHO Chief Scientist Dr Soumya Swaminathan says that it appears that vaccines are still proving to be effective

A fresh wave of the highly contagious Omicron Covid 19 strain has swept across the world leaving millions of people struggling each day to overcome it

Uzbekistan's first gas-to-liquids plant is being launched in the country's Farghona region

Chief Minister Basavaraj Bommai inaugurated an oxygen generator plant at JSS Hospital in the city on Sunday

Training programme of health care workers in public and private sector hospitals, diagnostic laboratories, blood banks by the NHSRC

An oxygen production plant with a capacity of 1,000 liters per hour has been set up in Mahabubnagar Government Hospital to overcome the oxygen scarcity during the pandemic

Air Separation Plants (ASPs) use air to separate natural gas liquids into marketable products

The global cryogenic oxygen plants and tanks market is anticipated to reach USD 1,788.4 million by 2025

Bihar Government will be holding a mock drill of pressure swing adsorption (PSA) -based oxygen generating plants in all the districts

Google Searches Annual Report of 2021

An Oxygen Plant produces liquid oxygen from air by dehumidifying and cooling the air.

Bhartiya Cryogas Limited is the leading Indian manufacturer and supplier of oxygen plants, dealing in large capacity O2 plant manufacturing systems

The Omicron variant of coronavirus is spreading at a rate not seen with any previous variant

Oxygen plants, also known as air separation plants or oxygen producing plants, produce most of the world's supply of liquid oxygen and are the principal source of gaseous oxygen.

Bhartiya Cryogas is one of the top oxygen manufacturers and suppliers to meet the requirements of government as well as private hospitals and healthcare facilities.

Bhartiya Cryogas, a leading manufacturer of commercial and medical grade oxygen in India which played a superlative role in meeting oxygen crisis

The air separation plant is a crucial part of the medical oxygen ecosystem. It produces high-purity gasses used to fill cylinders and smooth delivery of oxygen to patients.

Bhartiya Cryogas, top manufacturer and supplier of customized Cryogenic and PSA Medical Oxygen Generation plants rose to meet national crisis.

Surge in Corona’s latest variant Omicron cases in India has given rise to fear of possible third wave as per the India Medical Association (IMA) an umbrella body of doctors.

Acetylene is a highly explosive gas so it must be stored and handled with great care

Acetylene is made by passing a mixture of steam and air over calcium carbide. Carbide is a combination of calcium and carbon. The calcium and carbon separate in the heating process leaving the gases we all know as acetylene.

10 questions to learn important facts about Acetylene Gas

India is worried over the discovery of a new coronavirus variant

Commercial grade Acetylene is a colorless and odorless gas and may have a garlic or Ether like odor

There is a rise in demand for the Acetylene Plant in India and abroad to manufacture acetylene gases

Probe into Corona deaths due to oxygen shortage

Pan India Covid-19 wave may have subsided but infection is on rise in several areas making authorities nervous

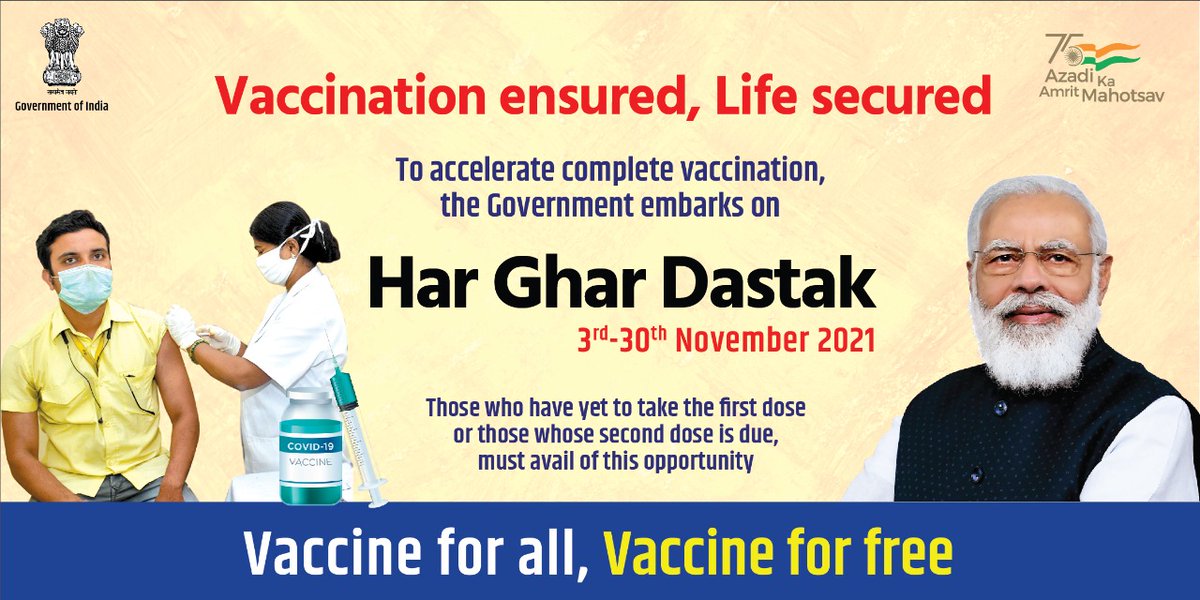

Prime Minister Narendra Modi launched an ambitious scheme to achieve universal anti covid vaccination for all adult population

Corona positive cases are on rise in Dakshina Kannada and Udupi area of Karnataka

The Delhi government is taking submissions for medical oxygen plants

WHO has warned that the delta strain of SARS-CoV-2 virus has been most dominant amongst all variants of concern

It is easy to concentrate oxygen as air already contains around 20.9 %

India seems to have a vast pool of skilled personnel

Oxygen business needs a number of documents

Cryogenic and PSA technology have unique pricing

The consumption of oxygen and nitrogen is required

We are the leading company around the world.

We designs and builds the plants using most up-to-date technologies.

We have a team of highly trained engineers and technicians with considerable experience in the design, fabrication, installation, and commissioning of various acetylene plants.

Our acetylene gas plants have capacities ranging from 15 to 200 m3/hr and are built using the most cutting-edge and adaptable designs.