- A-29, Industrial Area, Site IV,

Sahibabad, Ghaziabad, UP, India. - (+91-120) 2896063

info@bhartiyagroups.com

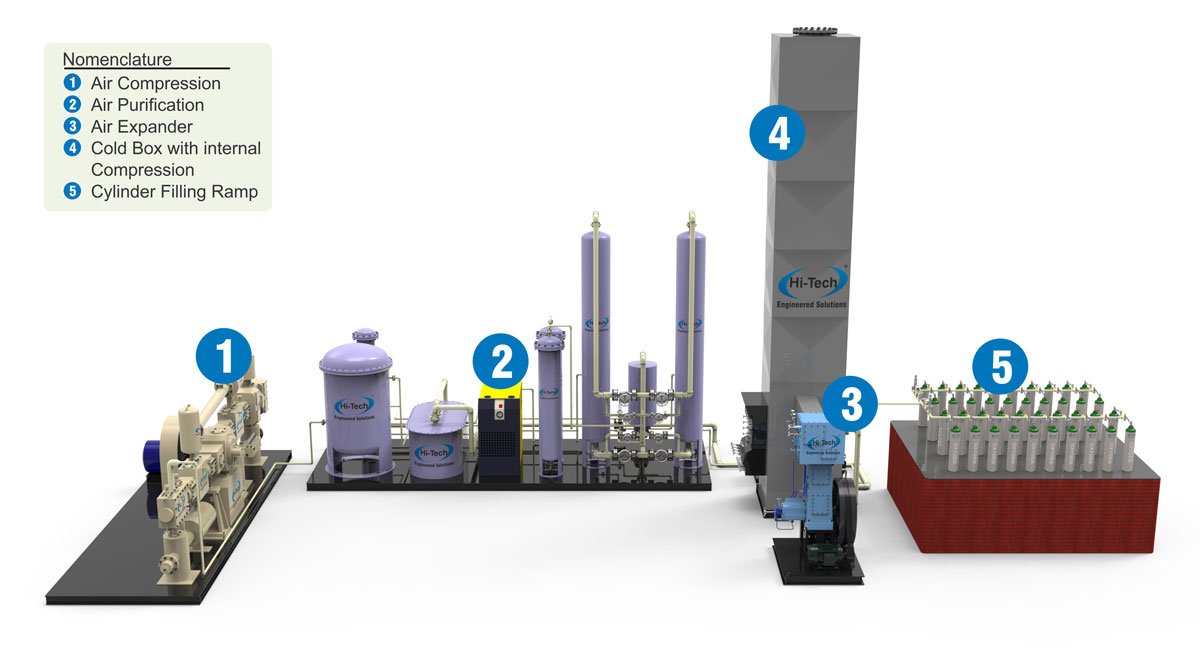

The most common production method for separation of oxygen is Air Separation Plants

Delhi government has issued an order to install telemetry devices on oxygen plants tanks

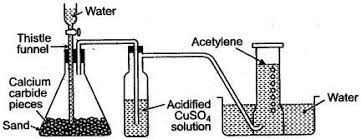

Acetylene plants produce acetylene from calcium carbide, air, and water

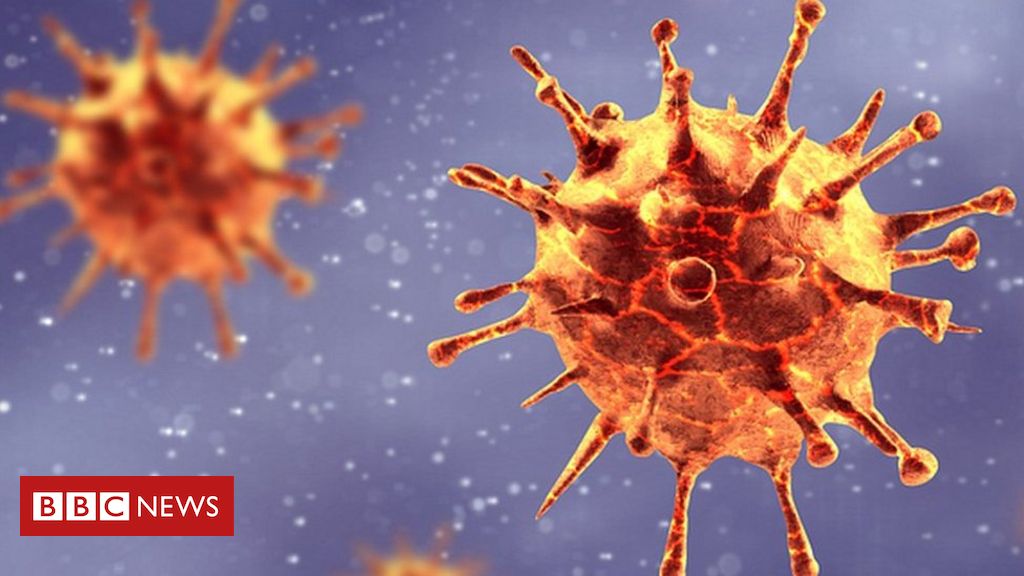

The new Covid variant Omicron cases continues to surge across India but oxygen requirements are still low among positive patients in comparison to the deadly second wave

Oxygen plays an integral role in a variety of industrial processes

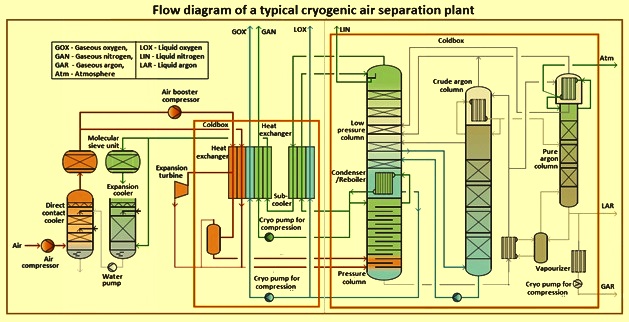

Separation of Air Components (Air Separation Plant or AS Plant) is a process that captures the basic components of air which are Nitrogen, Oxygen, and Argon, through separation processes

The government has scaled up oxygen production plants to 18,836 metric tonnes (MT) towards preparedness for the impending Covid-19 wave

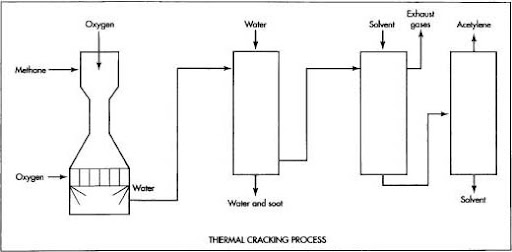

An acetylene plant is a process plant that converts different hydrocarbon gases such as natural gas, propane, butane and others into acetylene

The cryogenic oxygen plant is designed to take free air from the atmosphere containing moisture and bring down its temperature to a value below freezing point so as to liquefy it

Dr Angelique Coetzee -- the South African general practitioner who first very perceptively noticed the arrival of Omicron in patients in her surgery in Pretoria

WHO Chief Scientist Dr Soumya Swaminathan says that it appears that vaccines are still proving to be effective

A fresh wave of the highly contagious Omicron Covid 19 strain has swept across the world leaving millions of people struggling each day to overcome it

The government of Ukraine, in particular the Ministry of Finance, signed a contract for the purchase of 225 oxygen plants for COVID-19 patients

The 500-litre per minute oxygen production plant at Government Medical College, Jammu

Uzbekistan's first gas-to-liquids plant is being launched in the country's Farghona region

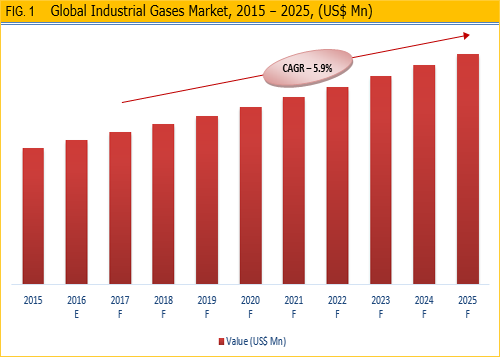

The Air Separation plant Market is estimated to grow from USD 15.46 billion in 2017 to reach USD 22.47 billion by 2026

A blast at the oxygen plant of Government Medical College (GMC), Baramulla

An acetylene plant is used to make acetylene gas. This process is called the "water gas reaction

Pressure swing adsorption (PSA) oxygen generating plants are a source of medical-grade oxygen

Chief Minister Basavaraj Bommai inaugurated an oxygen generator plant at JSS Hospital in the city on Sunday

The cryogenics oxygen plant produces on-site, high-purity oxygen for industrial production processes and for medical purposes

The Pressure Swing Adsorption (PSA) plant is the most used oxygen plant in the world

Training programme of health care workers in public and private sector hospitals, diagnostic laboratories, blood banks by the NHSRC

The cryogenic oxygen plant is an industrial facility that electrolytically produces liquid oxygen in large quantities

Cryogenics oxygen plant is used to freeze air or gas into liquid or solid state

An oxygen production plant with a capacity of 1,000 liters per hour has been set up in Mahabubnagar Government Hospital to overcome the oxygen scarcity during the pandemic

An acetylene plant is a chemical manufacturing facility that produces acetylene gas by the reaction of water and carbon dioxide by passing electricity

Air Separation Plants (ASPs) use air to separate natural gas liquids into marketable products

The global cryogenic oxygen plants and tanks market is anticipated to reach USD 1,788.4 million by 2025

Bihar Government will be holding a mock drill of pressure swing adsorption (PSA) -based oxygen generating plants in all the districts

Google Searches Annual Report of 2021

Air Separation Plants (ASPs) are gas separation facilities that use air, instead of liquid carbon dioxide, to separate the other gasses in natural gas streams.

An Oxygen Plant produces liquid oxygen from air by dehumidifying and cooling the air.

Bhartiya Cryogas is a Government of India company with the approval for manufacturing of acetylene gas from 1981

Bhartiya Cryogas Limited is the leading Indian manufacturer and supplier of oxygen plants, dealing in large capacity O2 plant manufacturing systems

Air Separation Plants (ASPs) are gas separation facilities that use air, instead of liquid carbon dioxide, to separate the other gasses in natural gas streams.

The Omicron variant of coronavirus is spreading at a rate not seen with any previous variant

Oxygen plants, also known as air separation plants or oxygen producing plants, produce most of the world's supply of liquid oxygen and are the principal source of gaseous oxygen.

Air separation plants allow you to use air as the carrier gas in cryogenic applications, displace the burden of liquid oxygen imports and costly liquid nitrogen refueling.

Bhartiya Cryogas is one of the top oxygen manufacturers and suppliers to meet the requirements of government as well as private hospitals and healthcare facilities.

Bhartiya Cryogas Hi Tech Private Limited is a reputed manufacturer and supplier of high quality 2-Ethyl Hexyl Acetylene and Acetylene Gas Plant.

Bhartiya Cryogas, a leading manufacturer of commercial and medical grade oxygen in India which played a superlative role in meeting oxygen crisis

The air separation plant is a crucial part of the medical oxygen ecosystem. It produces high-purity gasses used to fill cylinders and smooth delivery of oxygen to patients.

Bhartiya Cryogas, top manufacturer and supplier of customized Cryogenic and PSA Medical Oxygen Generation plants rose to meet national crisis.

Bhartiya Cryogas is top manufacturer of hi tech acetylene plants India. It’s fully automatic Acetylene plants are available

PSA plants are the most widely used oxygen plants in today's date because of their cost effective procedure

The global acetylene plants market was led by the U.S., followed by China, Japan, and Europe

Air Separation Plant (ASP), also known as Oxygen Plant or Oxygenation Unit, is a facility that produces oxygen.

Surge in Corona’s latest variant Omicron cases in India has given rise to fear of possible third wave as per the India Medical Association (IMA) an umbrella body of doctors.

CASU is designed to a specific application and offers a wide range of performance capabilities

Acetylene is a colorless, flammable gas with a vinegar odor

There are two ways to produce acetylene; you can use a chemical reaction process or you can use thermal cracking

Liquefied oxygen can be produced by combining liquid nitrogen and air at temperatures up to -162 degrees Celsius

PSA (pressure swing adsorption) oxygen plant is designed to produce and store high purity oxygen and nitrogen

Acetylene is a highly explosive gas so it must be stored and handled with great care

Acetylene was discovered in 1836, when Edmund Davy was experimenting with potassium carbide. One of his chemical reactions produced a flammable gas, which is now known as acetylene.

Acetylene is made by passing a mixture of steam and air over calcium carbide. Carbide is a combination of calcium and carbon. The calcium and carbon separate in the heating process leaving the gases we all know as acetylene.

Noel Dean Gravelle died quietly at the home of his son Warren and daughter-in-law Julie on October 27, 2021

10 questions to learn important facts about Acetylene Gas

India is worried over the discovery of a new coronavirus variant

The aim of the Global Acetylene Gas Cylinder Market 2021 research report is to get an accurate and comprehensive assessment of market share

Scientists have indeed been seeking for medicines to treat those that have been infected for nearly two years

The World Health Organization is "greatly worried" about just the recent Covid-19 outbreak in Europe

Covid-19 has already been detected in 28 girls visiting the Telangana Social Welfare Residential School in Wyra mandal

The highly infectious Delta form, have already been discovered to response well to a plant-based antiviral therapy

Commercial grade Acetylene is a colorless and odorless gas and may have a garlic or Ether like odor

There is a rise in demand for the Acetylene Plant in India and abroad to manufacture acetylene gases

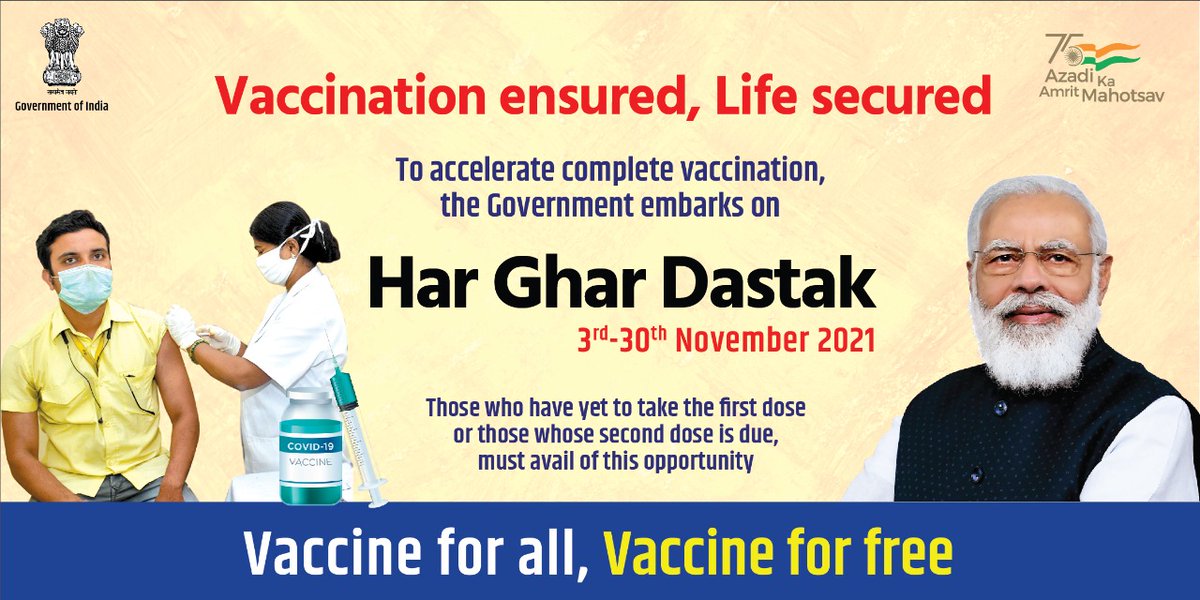

India’s Covid-19 vaccination drives continue to create new milestones

Probe into Corona deaths due to oxygen shortage

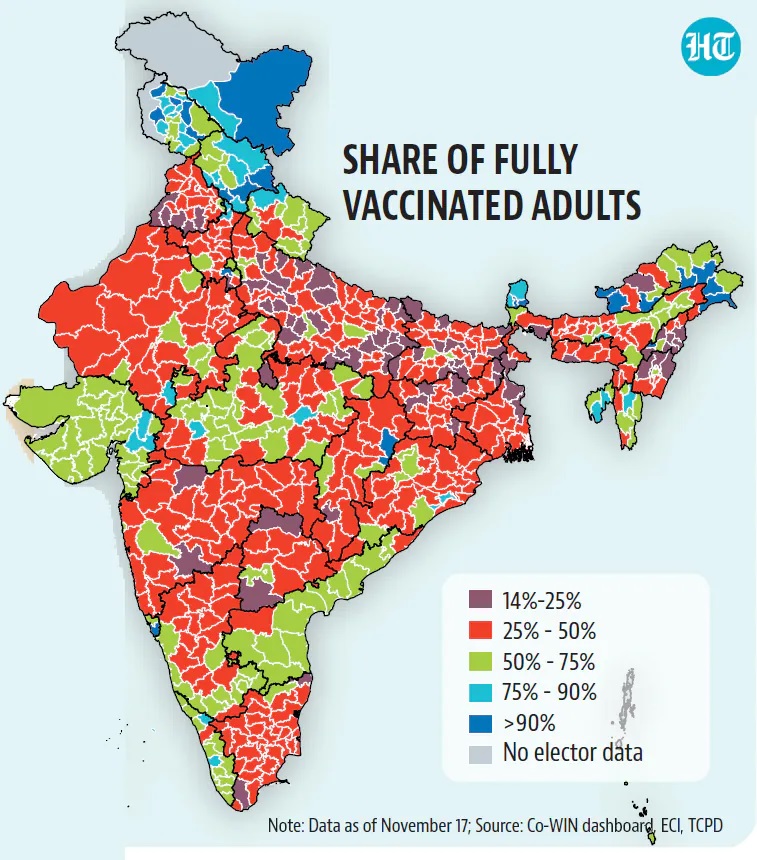

In 75 districts, the share of fully vaccinated adults is 25% or less and in almost ⅔ rd districts

Pan India Covid-19 wave may have subsided but infection is on rise in several areas making authorities nervous

Corona positive cases continue to rise in India as it recorded 10,197 new cases in the last 24 hours on November 17

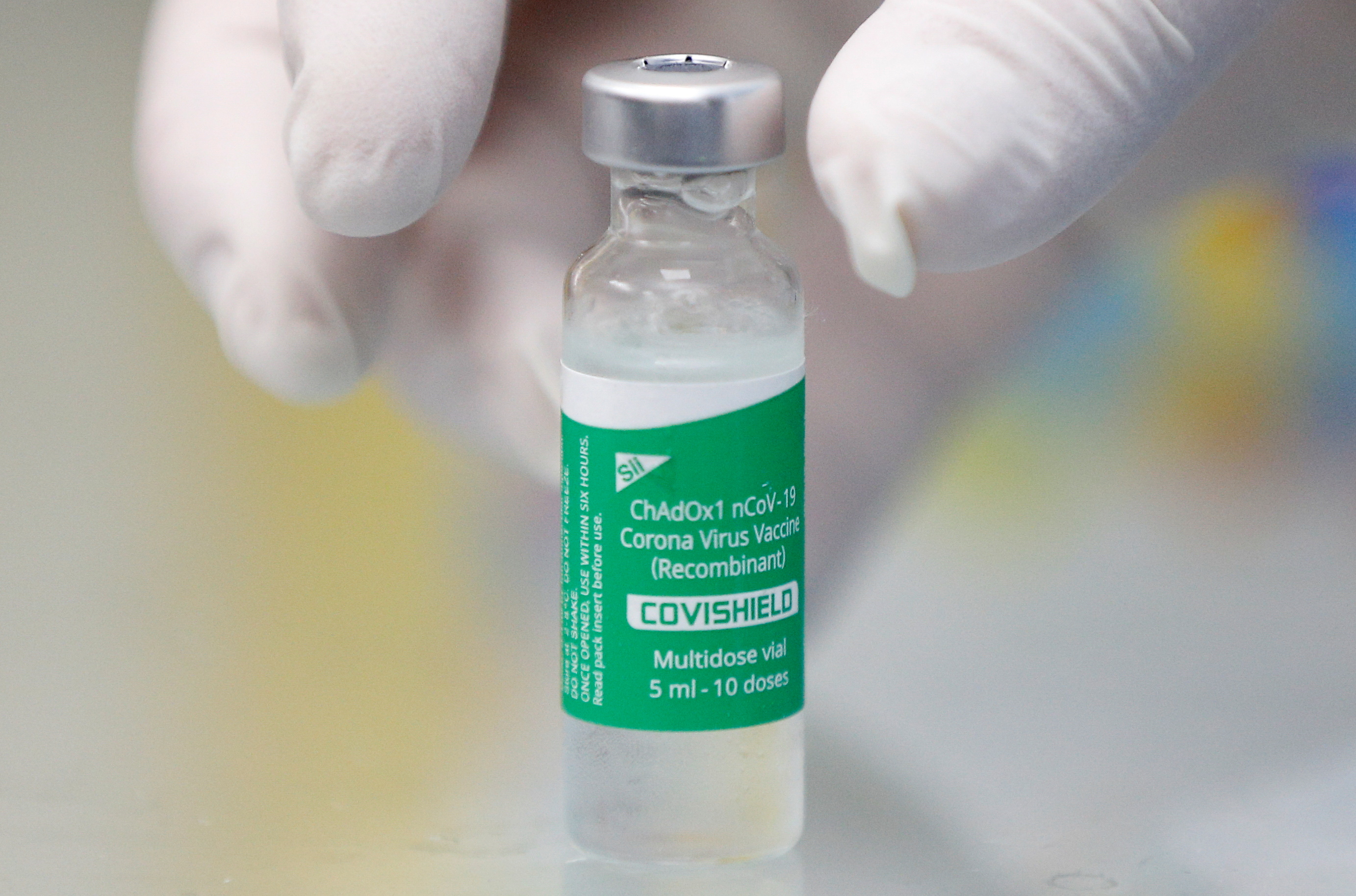

The Austrian Government has come out with a discriminatory policy when allowing foreigners to enter into their country having vaccination with Covishield, Sinopharm, or Sinovac

Prime Minister Narendra Modi launched an ambitious scheme to achieve universal anti covid vaccination for all adult population

Clean Energy is the key growth driver

Corona positive cases are on rise in Dakshina Kannada and Udupi area of Karnataka

After vaccines, pills to treat COVID-19 could be soon emerge as a successful weapon to fight against coronavirus spread

World Health Organization (WHO) Chief Scientist Dr Soumya Swaminathan warned that the there will be rise in Corona cases globally because virus due to multiple factors

The Delhi government is taking submissions for medical oxygen plants

WHO has warned that the delta strain of SARS-CoV-2 virus has been most dominant amongst all variants of concern

The senior family members including the 67-year-old man, his son and daughter-in-law were fully vaccinated against Coronavirus

After Srinagar, positive Covid cases are on the rise in Delhi

The capital city of Srinagar is in the grip of a third wave of coronavirus

The Delta variant caused the devastating second corona wave in the country

It is easy to concentrate oxygen as air already contains around 20.9 %

Coronavirus global outbreak has increased demand for the oxygen concentrators.

Our manufacturing complies to globally recognized processes and standards

There is high demand for oxygen in the country

Oxygen business needs a number of documents

oxygen plants in Mexico seemed to be an excellent choice by helping Bhartiya Cryogas

We are well-known for our service in the worldwide.

We have a team of highly trained engineers and technicians with considerable experience in the design, fabrication, installation, and commissioning of various acetylene plants.

Our acetylene gas plants have capacities ranging from 15 to 200 m3/hr and are built using the most cutting-edge and adaptable designs.